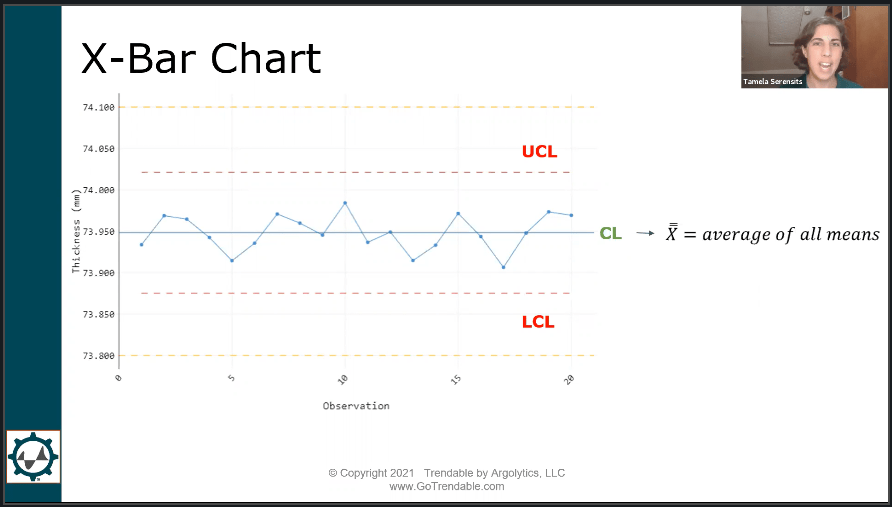

X Bar Chart

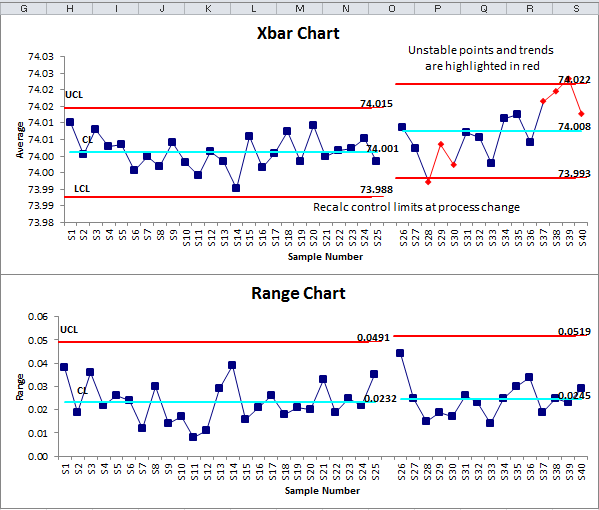

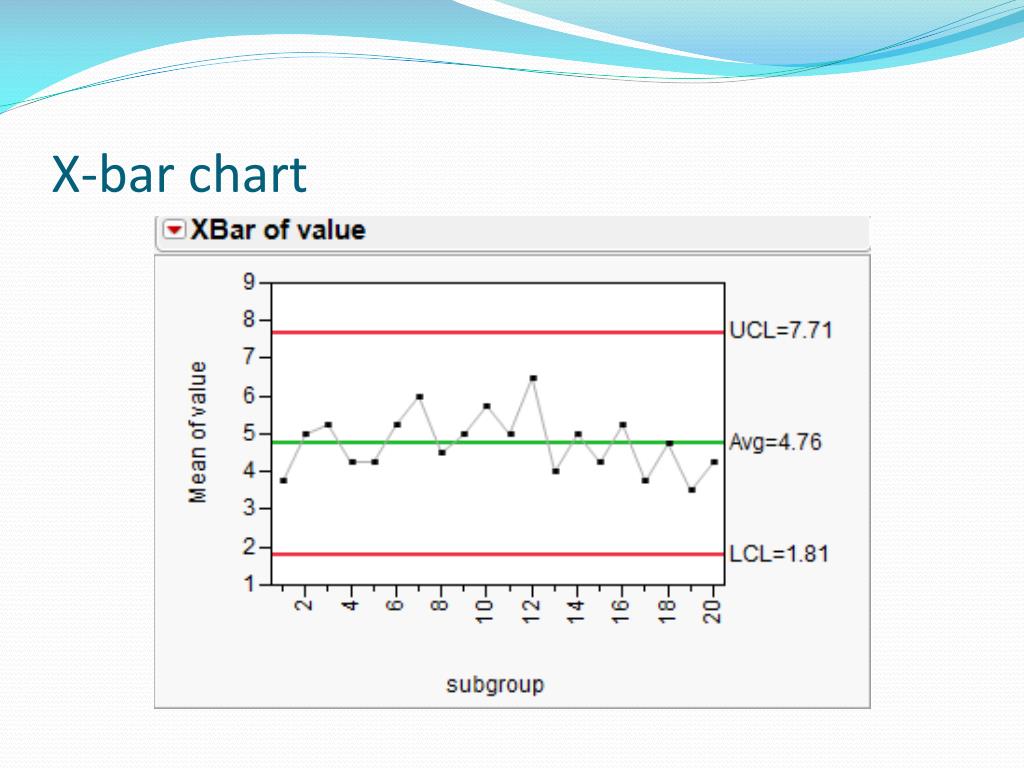

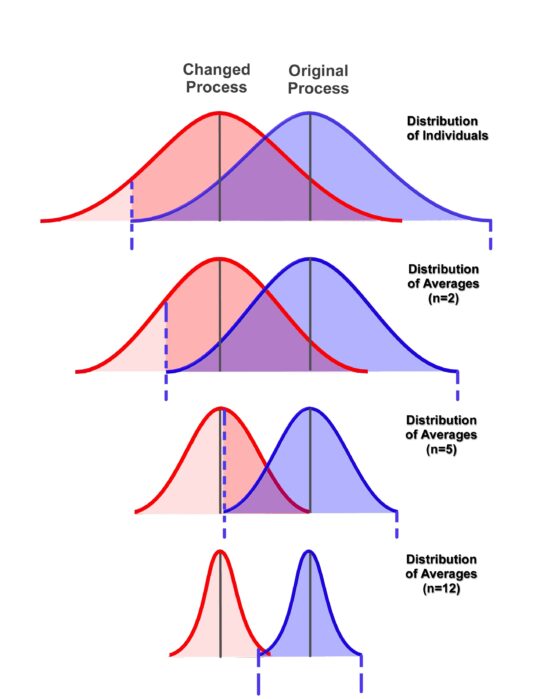

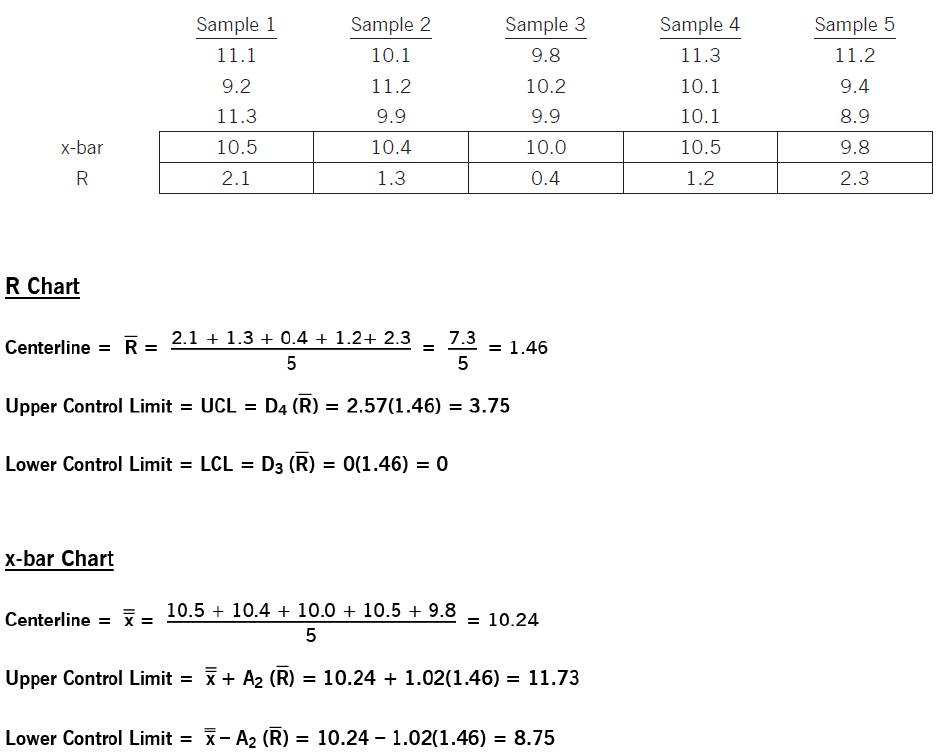

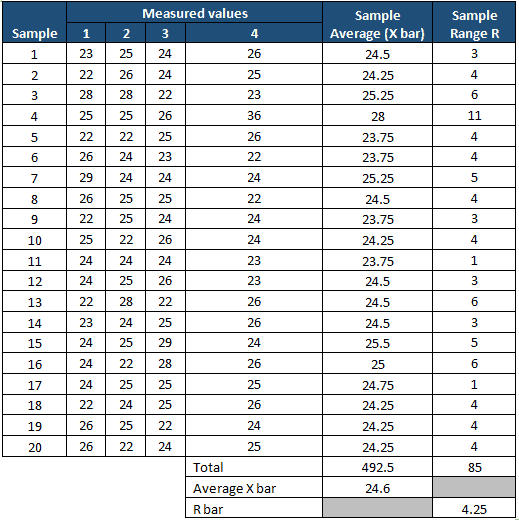

X Bar Chart - They provide continuous data to determine how well a process functions and stays within acceptable levels of variation. Here is some further information about the charts. The control limits on both chats are used to monitor the mean and variation of the process going forward. Analyzing the pattern of variance depicted by a quality control chart can help determine if defects are occurring randomly or systematically. Quality engineers at a manufacturing plant monitor part lengths. This type of control chart is used for characteristics that can be measured on a continuous scale, such as weight, temperature, thickness etc. Web x bar r charts are the widely used control charts for variable data to examine the process stability in many industries (like hospital patients’ blood pressure over time, customer call handle times, length of a part in a production process, etc). Analyzing the pattern of variance depicted by a quality control chart can help determine if defects are occurring randomly or systematically. Web x bar r charts are the widely used control charts for variable data to examine the process stability in many industries (like hospital patients’ blood pressure over time, customer call handle times, length of a part in a production process, etc). Quality engineers at a manufacturing plant monitor part lengths. The control limits on both chats are used to monitor the mean and variation of the process going forward. They provide continuous data to determine how well a process functions and stays within acceptable levels of variation. Here is some further information about the charts. This type of control chart is used for characteristics that can be measured on a continuous scale, such as weight, temperature, thickness etc. This type of control chart is used for characteristics that can be measured on a continuous scale, such as weight, temperature, thickness etc. Web x bar r charts are the widely used control charts for variable data to examine the process stability in many industries (like hospital patients’ blood pressure over time, customer call handle times, length of a part. Analyzing the pattern of variance depicted by a quality control chart can help determine if defects are occurring randomly or systematically. The control limits on both chats are used to monitor the mean and variation of the process going forward. Quality engineers at a manufacturing plant monitor part lengths. Here is some further information about the charts. Web x bar. This type of control chart is used for characteristics that can be measured on a continuous scale, such as weight, temperature, thickness etc. Analyzing the pattern of variance depicted by a quality control chart can help determine if defects are occurring randomly or systematically. The control limits on both chats are used to monitor the mean and variation of the. They provide continuous data to determine how well a process functions and stays within acceptable levels of variation. Here is some further information about the charts. Quality engineers at a manufacturing plant monitor part lengths. Web x bar r charts are the widely used control charts for variable data to examine the process stability in many industries (like hospital patients’. They provide continuous data to determine how well a process functions and stays within acceptable levels of variation. The control limits on both chats are used to monitor the mean and variation of the process going forward. This type of control chart is used for characteristics that can be measured on a continuous scale, such as weight, temperature, thickness etc.. Quality engineers at a manufacturing plant monitor part lengths. Web x bar r charts are the widely used control charts for variable data to examine the process stability in many industries (like hospital patients’ blood pressure over time, customer call handle times, length of a part in a production process, etc). This type of control chart is used for characteristics. They provide continuous data to determine how well a process functions and stays within acceptable levels of variation. Quality engineers at a manufacturing plant monitor part lengths. This type of control chart is used for characteristics that can be measured on a continuous scale, such as weight, temperature, thickness etc. Web x bar r charts are the widely used control. This type of control chart is used for characteristics that can be measured on a continuous scale, such as weight, temperature, thickness etc. Web x bar r charts are the widely used control charts for variable data to examine the process stability in many industries (like hospital patients’ blood pressure over time, customer call handle times, length of a part. This type of control chart is used for characteristics that can be measured on a continuous scale, such as weight, temperature, thickness etc. Quality engineers at a manufacturing plant monitor part lengths. Here is some further information about the charts. Analyzing the pattern of variance depicted by a quality control chart can help determine if defects are occurring randomly or. They provide continuous data to determine how well a process functions and stays within acceptable levels of variation. Quality engineers at a manufacturing plant monitor part lengths. Web x bar r charts are the widely used control charts for variable data to examine the process stability in many industries (like hospital patients’ blood pressure over time, customer call handle times,. They provide continuous data to determine how well a process functions and stays within acceptable levels of variation. This type of control chart is used for characteristics that can be measured on a continuous scale, such as weight, temperature, thickness etc. Analyzing the pattern of variance depicted by a quality control chart can help determine if defects are occurring randomly or systematically. Web x bar r charts are the widely used control charts for variable data to examine the process stability in many industries (like hospital patients’ blood pressure over time, customer call handle times, length of a part in a production process, etc). Quality engineers at a manufacturing plant monitor part lengths.X Bar R Chart Example

Quality Control Charts xbar chart, schart and Process Capability

How To Create an XBar R Chart Six Sigma Daily

What is an Xbar control chart? TRENDABLE

X Bar R Control Charts

Xbar chart for a paired Xbar and s Chart [29] Download Scientific

X Bar R Chart Excel Average and Range Chart

PPT Xbar and R charts PowerPoint Presentation, free download ID

A2 Chart For X Bar

What is a good way to select subgroup size for an Xbar Chart

The Control Limits On Both Chats Are Used To Monitor The Mean And Variation Of The Process Going Forward.

Here Is Some Further Information About The Charts.

Related Post:

![Xbar chart for a paired Xbar and s Chart [29] Download Scientific](https://www.researchgate.net/publication/331626425/figure/fig1/AS:734382528659456@1552101847715/bar-chart-for-a-paired-X-bar-and-s-Chart-29.jpg)